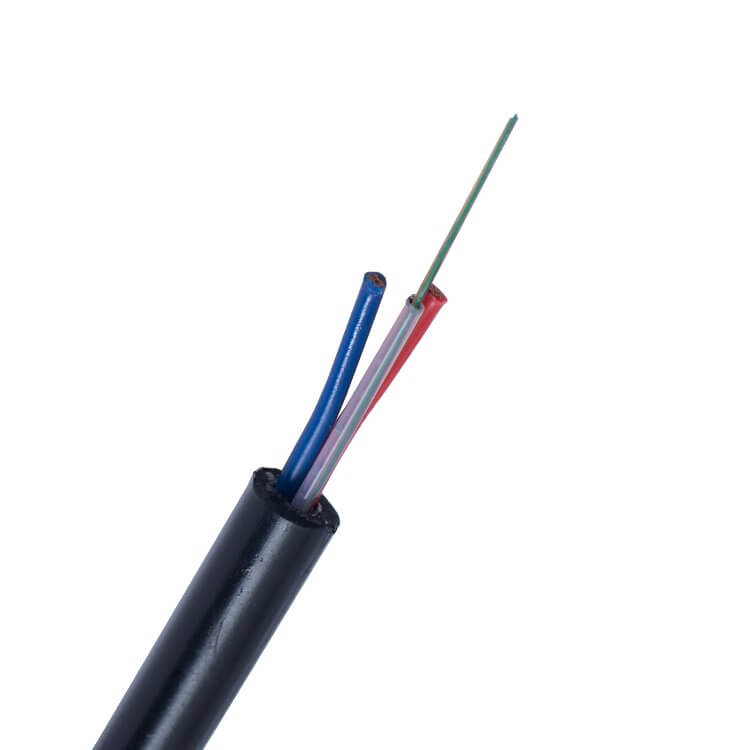

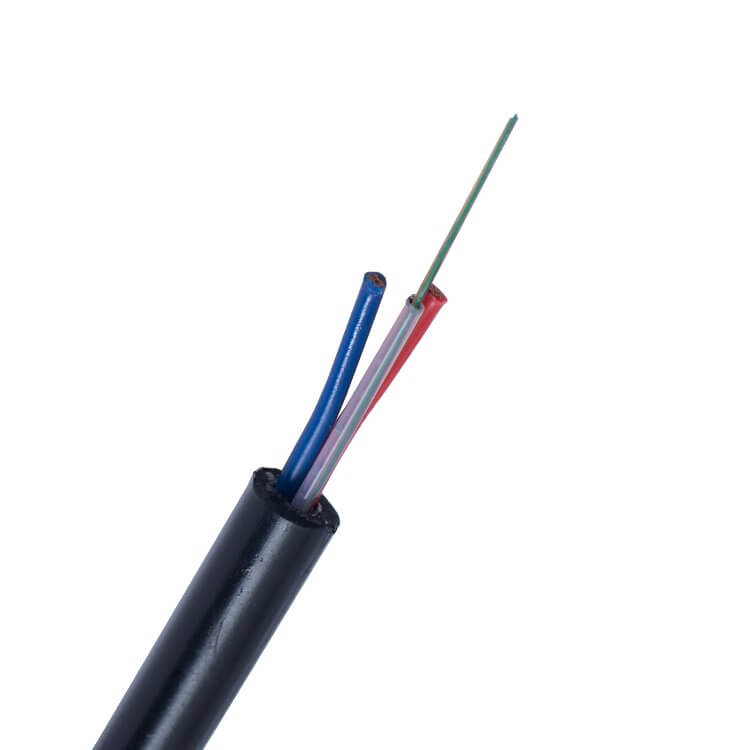

Hybrid Fiber Optic Cable

Hybrid fiber optic cable is the structure which optical fiber and insulated copper conductor are placed inside at the same time, so that one cable can solve the transmission of power and signal at the same time.

This composite hybrid fiber power cable is mainly used to connect BBU and RRU in DC remote supply system of distributed base station. And the voltage of DC remote supply system is usually DC 380V. There are usually two wires in the hybrid cable, and the cross-sectional area (mm2) of the copper wire is mainly related to the power and transmission distance of the remote communication equipment.

Hybrid fiber optic cable can be laid overhead or in pipeline. From the perspective of safety, hybrid cable line belongs to strong current line, and safety should be paid attention to in construction and maintenance.

Anti Rat Bite Fiber Cable

The structure of anti rat bite fiber cable is the same as that of directly buried optical cable, except that the corrugated steel tape of armor layer is made of stainless steel. This special optical fiber cable has high anti bite and anti-corrosion characteristics.

It is mainly used in the field farmland, forest and other areas where voles, squirrels and woodpeckers are active. It can be laid overhead, pipeline or directly buried.

Air Blown Fiber Cable

Air blown fiber, commonly known as air blown micro cable, adopts the structure of non-metallic reinforcement and no armor. It can be laid by laying micro pipe in the communication pipeline and then air blowing the micro cable in the micro pipe. The distance of one air blowing installation can reach 1km.

The outer diameter of air blown fiber cable is relatively thin, which can effectively use the existing pipe hole space. The number of commonly used air blown fiber is 36, 48, 72, 96 and 144 cores.

Air blown fiber cable shall be laid in microtubules, which is suitable for scenes with long section length where the number of optical cable cores does not decrease, such as trunk line and metropolitan backbone network. And the air blown fiber is not suitable for use in community broadband access network.

Underwater Fiber Optic Cable

Underwater fiber optic cable is a kind of optical cable that can be used underwater and underground. It is also called reinforced directly buried fiber optic cable. This special optical fiber cable can be understood as a cable formed by extruding the polyethylene outer sheath after being armored with one or two layer of round steel wire outside the sheath of a common duct fiber optic cable.

The underwater fiber cable has strong waterproof, tensile and lateral pressure resistance. According to the tensile strength, this special optical fiber cable can be used for

- direct buried laying in mountainous areas, hills, other areas with high tensile resistance requirements

- underwater laying with stable riverbed and beach and low velocity

- unstable riverbed and beach, flow velocity greater than 3m/s or main navigable rivers

- unstable riverbed and beach, serious scouring and super large rivers with river width of more than 500m

Ming Fiber Optic Cable

The mining fiber optic cable is also known as flame retardant fiber optic cable. It has the same structure as common direct burial fiber optic cable. The difference is that the outer sheath of regular direct buried optical cable is polyethylene material, and the outer sheath of the flame retardant optical cable is flame retardant material.

Mining fiber optic cable is a special optical fiber cable that must be used in the high standard requirements of high-speed railway and subway due to the restrictions of industrial specifications.