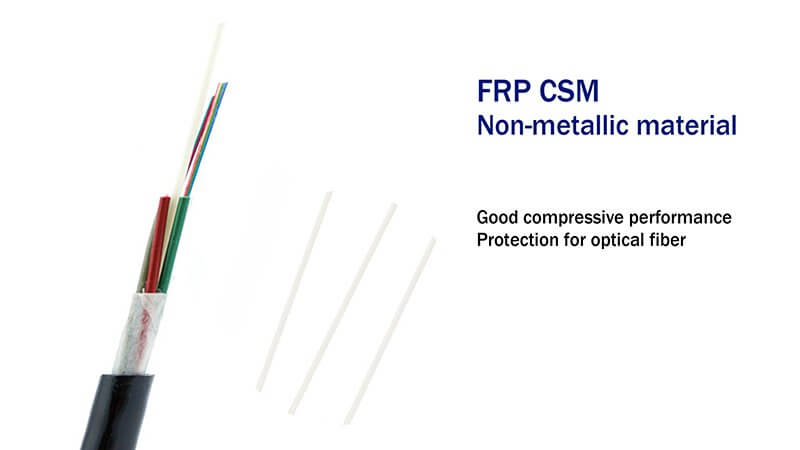

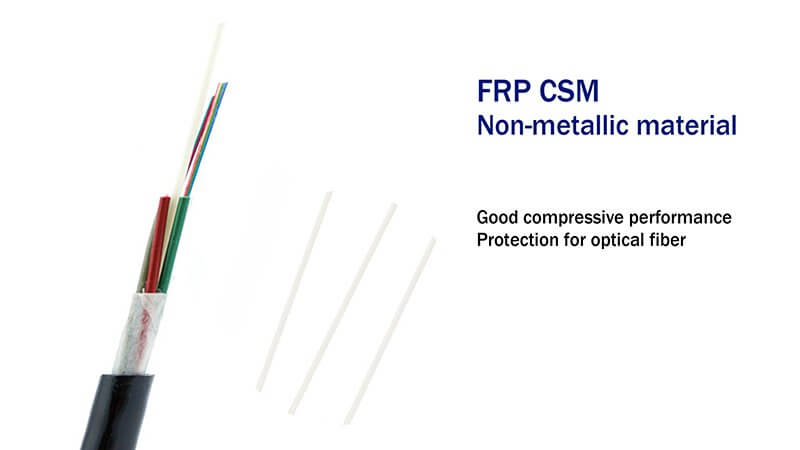

FRP is Fiberglass-Reinforced Plastic. As a strength member, the FRP fiber optic cable reinforcement core is an important component of the fiber optic cable.

Its function is to support the fiber unit or fiber bundle and improve the tensile strength of the fiber optic cable. As a cental strength member (CSM) material, it is generally placed in the center of the fiber optic cable.

It is the metal reinforcements that has been used in traditional fiber otpic cables. While the FRP non-metallic reinforcements are increasingly used in various optical cables with their advantages of light weight, high strength, corrosion resistance, and long life.

How About FRP

The reinforced core (glass fiber) of FRP is a new type of high-performance engineering composite material prepared by using resin as the matrix material, glass fiber as the reinforcing material, mixed in proportion and using the pultrusion process.

Non-metallic FRP fiber optic cable reinforcement overcomes the defects of traditional metal fiber optic cable reinforcement.

It has excellent corrosion resistance, lightning resistance, electromagnetic field interference resistance, high tensile strength, light weight, environmental protection, and energy saving. It is widely used in all kinds of optical cables.

Advantages of FRP

Lightweight and high-strength

The relative density of FRP is between 1.5~2.0, which is only 1/4~1/5 of carbon steel. But the tensile strength is close to or even higher than that of carbon steel. And the specific strength can be compared with high-grade alloy steel.

Therefore, it has excellent results in aviation, rockets, space vehicles, high-pressure vessels, and other products that need to reduce their own weight. The tensile, flexural and compressive strengths of some epoxy FRP can reach more than 400Mpa.

Good corrosion resistance

FRP is a good corrosion-resistant material, and has good resistance to the atmosphere, water, and general concentrations of acids, alkalis, salts, and a variety of oils and solvents. It has been applied to all aspects of chemical corrosion protection and is replacing carbon steel, stainless steel, wood, non-ferrous metals, etc.

Compared with metal CSM such as steel wire, FRP reinforced rod will not produce gas generated by the chemical reaction of metal and ointment, which will affect the optical fiber transmission index.

Good Electrical Properties

FRP is also an excellent insulating material, which can be used to make insulators. It can still protect good dielectric properties under high frequency. It has good microwave permeability and has been widely used in radomes, and many more.

The optical cable with FRP fiber optic cable reinforced rod can be installed next to the electrical cable and power supply device. And it will not be interfered by the induced current generated by the electrical cable or power supply device. They are also suitable for climatic environments such as thunder and lightning, and rain.

Steel Wire CSM

As the center of the fiber optic cable’s reinforcing core, the fiber optic cable initially used galvanized steel wire as the fiber optic cable central strength member material. But now it has basically replaced by phosphating steel wire.

steel wire is also used as other protection member in fiber optic cable

Phosphating steel wire can protect the optical fiber material from bending in the optical cable, play a role of supporting and strengthening the frame, which is conducive to optical cable manufacturing, storage and transportation, and the laying of optical cable lines.

It has the advantages of stabilizing the quality of the optical cable and reducing signal attenuation.

Applications

FRP

Aramid and FRP can be used together to make non-metallic fiber optic cables, which are mostly used in indoor environments because they are safer.

Sometimes it is also used in outdoor environments, such as ADSS fiber optic cables used in power systems. Since there is no metal component in the ADSS cable, it will not be disturbed by lightning, and there is no risk of fire and breakdown at the joint.

Steel Wire

The advantages of using steel wire as central strength member is that steel wire has high strength and strong resistance to lateral pressure. Therefore, it is usually used in outdoor environments, such as overhead, pipelines, direct burial, and underwater.

Summary

In terms of price, there is no direct comparability between FRP and steel wire as central strength member, and the application environment should always the most priority.

For instance, a non-metallic fiber optic cable is not suitable for the outdoor direct burial environment. While metal fiber optic cables are not suitable for indoor network as well. If we have to compare, the price of FRP is definitely more expensive than the metal materials under the same mechanical strength.